Wednesday, May 30, 2007

I am unable to post photos at the moment, but a photo gallery of the construction is available here http://www.pbase.com/bmcmorrow/dxbburjdubai&page=all

Its top floor will be 624 windows high, nearly 70 metres taller than the next tallest building, and a spire which reaches 818 metres high. The Footings alone required some 45000 cubic metres of concrete, and weighed 110000 tonnes. The first 88 floors are to be built of reinforced concrete, with the remaining floors being structural steel framing. The exterior cladding will consist of 'reflective glazing with aluminum and textured stainless steel spandrel panels with vertical tubular fins of stainless steel.'

The original plan was taken from the propsed Grollo tower in Melbourne, but was replaced with the current plan, which better suits its Islamic context.

The building will brake all records, at least until the finalization of the design of Freedom tower in the USA, which is likely to become the next record braker.

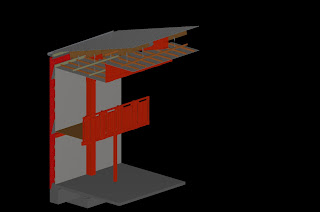

Above is a metal saddle exposed column connection between the box beam and the purlin.

I connected the Column to the ground with a modification of the U-Bracket upon a metal upstand which is found in the NAFI Timber Joint Design Manual. I placed the steel support within the Box beam instead of around. I also hid the rise, which is built to prevent ground water reaching the column, by building a box around the steel. The box would appear from the outside to be simply a continuation of the column, but in fact is separated by a 20 mm gap to, and is not a structural component of the column.

I was unable to create a photo of this detail, as well as many others I spent a long time building. I did not know how to render in microstation, and so I was dissapointed with the result, as the images I created did not show the full extent of the detail. For this reason I submitted the model itself on a CD, in the hope that this can be marked instead of the images.

CSR Gyprock

http://www.gyprock.com.au/Gyprock/default.asp

Especially good for wall and cieling detailing. The Red Book is an all in one brochure, which I obtained a copy of from their office in Fyans St. It is also available online.

Bluescope Steel

http://www.bluescopesteel.com.au/

Gave a wide range of roofing profiles from which I chose.

Timber Building in Australia

http://oak.arch.utas.edu.au/tbia/links.asp

Very useful on the subject of Portal frames. Used along with the Timber Manual I found in the library which gave me more detailed joining techniques. They did however provide some conflicting information, especially regarding how to construct the knee joint.

Boral Timber Products

http://www.boral.com.au/

Gave options for how to construct the timber decking and ballustrade

Tuesday, May 29, 2007

I decided to look into the places in the world with the biggest construction booms, and the types of construction they are undertaking.

The most obvious place is Biejing, in preparation for the 2008 Olympics. At current, 1/2 of the worlds steel production and 1/3 of the worlds concrete are being used in China alone. Beijing itself is being rebuilt, in particular a new airport, transport system, and new hotels and sporting arenas are being built at a pace never before seen in any other country.

The most obvious place is Biejing, in preparation for the 2008 Olympics. At current, 1/2 of the worlds steel production and 1/3 of the worlds concrete are being used in China alone. Beijing itself is being rebuilt, in particular a new airport, transport system, and new hotels and sporting arenas are being built at a pace never before seen in any other country.The China World Trade Centre will be the tallest building in Beijing at 330 metres and with 80 stories. Designed by the architects Skidmore, Owings & Merrill LLP, its construction has and will be rushed to have it completed in time for the Olympics. Work progresses through the entire day, with people working upon the steel through the day, and the cranes working at night. The hurrying of construction by the Chinese government has come into the press recently, with the deaths of six construction workers several days ago.

To help support the industrialisation of their cities, the Chinese Government has also funded the construction of the Three Gorges Dam. This project has been extremely controversial, as it has required the relocation of 1.13 million people, all but run the Yangtee river dry at the basin, flooded millions of acres of China's best farm land, and is proven not to be the most effective way of harvesting energy from the river.

To help support the industrialisation of their cities, the Chinese Government has also funded the construction of the Three Gorges Dam. This project has been extremely controversial, as it has required the relocation of 1.13 million people, all but run the Yangtee river dry at the basin, flooded millions of acres of China's best farm land, and is proven not to be the most effective way of harvesting energy from the river. It is however, one of the greatest feats of construcion in the world, and by far the largest dam ever made. Made of concrete, the dam stretches 2335 metres long, and 185 high, is 115 metres wide at the bottom, and 40 high at the top. It consumed a total 28 million cubic metres of concrete and 463 thousand cubic metres of steel. It was opened on May 20 2006, but several genaerators, as well as the shiping locks system are yet to be completed. To date, the total cost has been 22.5 billion dollars.

It is however, one of the greatest feats of construcion in the world, and by far the largest dam ever made. Made of concrete, the dam stretches 2335 metres long, and 185 high, is 115 metres wide at the bottom, and 40 high at the top. It consumed a total 28 million cubic metres of concrete and 463 thousand cubic metres of steel. It was opened on May 20 2006, but several genaerators, as well as the shiping locks system are yet to be completed. To date, the total cost has been 22.5 billion dollars.China's development has come at a price to the environment, in particular, the growth of the Gobi Desert. This has caused an increase in the severity of dust storms in Beijing, which is being dealt with through the construction of the 'Great Green Wall.' This is in affect, a 4480 kilometre network of forest plantations, which will shelter Beijing from the winds.

Monday, May 21, 2007

Charles Rennie Mackintosh believed 'construction should be decorated and not decoration constructed.' I have decided to use a lowered ceiling, and decorative balustrade to reflcect his style. The ceilings profile reflects alot of his work, as a long taut sweeping curve.

I have tried to proportion the features of the two buildings to hide their different sizes. The windows are therefor larger on the small building, as are the enterances. Mackintosh used this technique for the Glasgow School Of Art.

Tuesday, May 8, 2007

Builder: Westfield Construction

Date: 04/05/07

This project is using precast panels, concrete flooring and steel for an extension of the shopping centre, and parking lot. The redevelopment is tying in the new structure with the existing concrete structures.

Below the concrete columns with reinforcement extending from thier tops can be seen. These columns were joined to the existing structure by removing the top of the existing columns to expose the reinfrocement, then tying this reinforcement into that of the new columns.

Below, the falsework (the braced steel structure) supporting the cement floor can be seen. The falsework supports the formwork (the timbers) which frame the shape of the concrete.

Below, the falsework (the braced steel structure) supporting the cement floor can be seen. The falsework supports the formwork (the timbers) which frame the shape of the concrete.

Below, the reinforcement extending out of the pad footing is left bare, waiting for a strip footing and concrete columns to be constructed on top of it. The reinforcement that can be seen will be tied in with that of these elements.

AGM Builder

Date :

Below are steel connections used in the bendigo bank project. The first is a connection between two Universal Beams, supporting the 2nd floor. I believe the larger beam acts as a joist, and the smaller one, as a purlin. It can be seen that this purlin requires a length of its top flange to be removed so it may sit flush against the beam. The second detail is this same connetion over a concrete/steel composite column. I do not know why the steel comumn extends past the height of the concrete, separating the joint from the column. Could anyone tell me why this is needed?

Below are steel connections used in the bendigo bank project. The first is a connection between two Universal Beams, supporting the 2nd floor. I believe the larger beam acts as a joist, and the smaller one, as a purlin. It can be seen that this purlin requires a length of its top flange to be removed so it may sit flush against the beam. The second detail is this same connetion over a concrete/steel composite column. I do not know why the steel comumn extends past the height of the concrete, separating the joint from the column. Could anyone tell me why this is needed?

Below are photos of the formwork upon the second floor. In the first photo the steel reinforcement which covers the condek floor can be seen. The second photo shows the formwork surrounding the top of a concrete column, so its reinforcement may be tied in to another column which extends up to the next floor.